Third-party Transceiver Solutions for Ubiquiti Switches

As we all know, Ubiquiti is a famous company that provides various kinds of switches, including Edge Switch, Edge Router, UniFi Switch. What does attract more attention is, this company firstly published its own SFP and SFP+ fiber optic transceiver, compatible with its switches last year. Meanwhile, it also published that third-party fiber transceivers from some fiber optic transceiver manufacturers like Cisco, Brocade and FS.COM are compatible with the Ubiquiti switches, too. In this paper, it will mainly talk about which kinds of third-party fiber transceivers can support the Ubiquiti switches and which fiber optic transceiver manufacturers can offer the most reliable third-party fiber transceivers.

Ubiquiti mainly provides switches for 1G and 10G Ethernet network. Until last year, they began to offer a small amount of single mode and multimode fiber transceivers to support the Ubiquiti switches. For instance, the UF-MM-1G and UF-SM-1G-S 1000Base SFP transceivers are used for the SFP ports on the Ubiquiti switches, while the UF-MM-10G, UF-SM-10G and UF-SM-10G-S 10GBase SFP+ transceivers are designed for connecting the SFP+ ports on the Ubiquiti switches.

Apart from their own fiber transceivers, there are also some other branded fiber transceivers tested on the Ubiquiti switches and confirmed to be compatible with Ubiquiti switches, such as Cisco, Brocade, Dell, HP, Finisar branded fiber transceivers. Just taking Cisco, the world famous fiber optic transceiver manufacturer as an example, it offers six kinds of SFP transceivers to support the Ubiquiti switches, Cisco GLC-LH-SM 30-1299-01 SFP, Cisco GLC-SX-MM, Cisco GLC-SX-MM 1000BASE-SX SFP, Cisco SFP-H10GB-CU1M, Cisco MGBSX1 Gigabit SX Mini-GBIC SFP Transceiver and Cisco GLC-T. Besides, for 10G network, the Cisco SFP-10G-SR can be inserted in SFP+ ports on the Ubiquiti switches.

After aquiring these basic information of transceivers for Ubiquiti switches, here also offers FS.COM transceiver solutions for Ubiquiti switches. FS.COM, a third-party fiber transceiver manufacturer, offers various kinds of SFP and SFP+ transceivers to support the Ubiquiti switches, such as, SFP1G-LX-31 1310nm (single mode SFPs), SFP-1G85-5M (multi-mode), SFP-GB-GE-T module, SFP-10G85-3M (multi-mode). These mentioned transceivers have been spoken highly of by many users at FS.COM.

From the text above, we can learn that except for their own transceivers, there are also many third-party fiber transceivers designed for supporting the Ubiquiti switches, for instance, Cisco, Brocade and FS.COM. Then here comes an important question, which kind of third-party fiber transceiver is more reliable for the Ubiquiti switches? In this paper, the suggestion is FS.COM fiber transceiver and the following will give you the reasons.

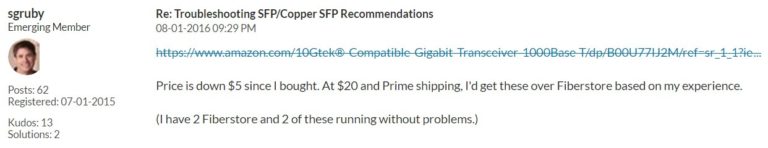

The first reason is that there are enough SFP and SFP+ transceivers offered for their corresponding Ubiquiti switches and those SFP and SFP+ transceivers have been tested to be suitable for the Ubiquiti switches. The second reason is that the SFP and SFP+ transceivers offered FS.COM are of high quality and good price. If you have ever bought the SFP and SFP+ transceivers with low price from some other fiber optic transceiver manufacturers, you may experience the quality of those fiber transceivers which generally can’t be assured. But in FS.COM test center, each fiber transceiver offered by FS.COM before shipping has to go through strict test on the switches from Cisco, Dell, Extreme, Juniper and other famous brands to assure 100% compatibility and high performance. Here offers the figures that shows the feedback about the quality and price for FS.COM fiber transceivers from users.

When choosing SFP and SFP+ transceivers for your Ubiquiti switches, have you ever hesitated over which fiber optic transceiver manufacturer should be chosen? Buy from Ubiquiti? Or other third-party fiber transceiver manufacturer? In fact, the selection should be made after considering the quality and price of the transceiver and the after-sales service the fiber transceiver manufacturer offers. Taking these factors into consideration, FS.COM should be a good choice for meeting your fiber transceiver needs.

Direct Attach Cable Assemblies Solution in Data Center

In general, the direct attach cable assemblies can be simply divided into two types, fiber type that can be called active optical cable (AOC), and copper type which basically includes active and passive direct attach copper cable (DAC), designed to support high transfer rates between servers, switches and storage devices intra rack or inter rack in data center. These direct attach cable assemblies have the same ports as their corresponding fiber optical modules, for instance, the SFP+ passive copper cable is fitted with SFP+ port, and QSFP+ passive copper cable with QSFP+ port. They are the ideal alternative to the fiber optical modules in high transfer rate and short distance applications for much lower cost and power consumption. Thereby, the direct attach cable assemblies become more and more commonly used for short distance network deployment.

The active optical cable consists of active electrical and optical components, which can transmit signals at lengths up to 100 m through multimode fiber cable. The most special active optical cable is the cable designed with fan-out technology like QSFP to 4xSFP+ AOC and 40G QSFP+ to 8xLC AOC for better satisfying the requirement of network migration from 10G to 40G. As for the internal structure of the active optical cable, you can learn it from the following figure.

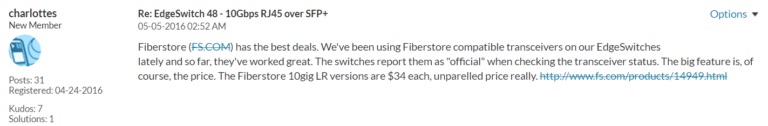

At present, there are two kinds of direct attach copper cable. One is the active direct attach copper cable like SFP+ active copper cable, and the other is passive direct attach copper cable like QSFP+ passive copper cable. Compared to the fiber one, these two kinds of direct attach copper cables can support the 10G and 40G signals with shorter distance. As for the active direct attach copper cable, it features active component that can achieve the interconnection up to 15 m at 10 Gbps or 40 Gbps, but it also requires more power to boost/receive signals. As for the passive direct attach copper cable, it has no any active circuitry components which can only reach 7 m at 10Gbps or 40 Gbps at most, with low power. The figure below shows the differences between active and passive direct attach copper.

There is no doubt that the direct attach cable assemblies are good choices for short distance direct connection, usually applied in the EDA (Equipment Distribution Area) where the cabinets and racks house end equipment (servers) and where the horizontal cabling from the HDA (Horizontal Distribution Area) is terminated at patch panels. In details, the direct attach cable assemblies are used for connecting the server with the switch, the storage with the switch, or the switch with the switch in racks and between rows of racks. Besides, various length selections for the direct attach cable assemblies such as SFP+ passive copper cable and QSFP+ active copper cable can be ordered to meet different connection requirement.

With the popularity of 10G Ethernet network, the 10G SFP+ DAC (within 15 m) and 10G SFP+ AOC (within 100 m) occupy the major direct attach cable assemblies market for interconnection in the same rack or between rows of racks at present. Meanwhile, the SFP28 DAC is also designed for 25G Ethernet network which may gradually replace the 10G SFP+ DAC for higher transfer rate. What’s more, for meeting the fast development of Ethernet network, 40G QSFP+ DAC for short interconnection no longer than 15 m and 40G QSFP+ AOC for longer interconnect application that over 15 m but less than 100 m are also available for 40G Ethernet network. If these direct attach cable assemblies still can’t satisfy your requirement, then the 100G QSFP28 DAC and AOC are highly recommended for you to deploy in the 100G Ethernet network.

Two Suggestions for Deploying 10G SFP Direct Attach Copper Cable

Have you ever used the Cisco direct attach SFP+ twinax cable for connecting Cisco switches, as a cost-effective alternative to Cisco SFP+ transceivers for short-distance, high-speed connection? Or choosing other branded 10G SFP direct attach copper cables (DACs) to connect their corresponding devices? In fact, the SFP+ DAC becomes much more popular than ever before for its lower cost and easier installation than the SFP+ transceiver. You only need to incorporate the SFP+ DACs into the physical infrastructure directly, then the connection can be finished without any additional signal processing or conversion. However, although the SFP+ DAC is very easy to install, there are still two suggestions you should pay attention to if you choose it to deploy 10G short-distance connection.

Before deploying your 10G short-distance connection, it is very important to design and calculate the length of the SFP+ DACs your network needs, avoiding many cables waste or lack of cables when deploying. How to calculate it? Just taking the single 84 in. 45 RU cabinet shown in the following figure as an example. As the cabinet is fitted with 2 top of rack switches and 20 2U servers with dual SFP+ NICs (Network Interface Cards), totally 40 SFP+ DACs are required. If you prepare to deploy the SFP+ DACs in the cabinet, you should firstly calculate the longest connection from the top to the bottom of the cabinet, which is about 7 ft. or 2.1 m, and secondly the connection to any port on either end, approximately 1.5 ft. or 0.45 m. Then you can conclude that the longest cable required to reach the farthest port is 2.1+2×0.45≈3 m. Hence, a 3m SFP+ DAC should be long enough to connect any two ports within the cabinet.

Since the bundled cable would be very heavy and tend to sag over time, the cable management tools like cable managers, strain relief bars and cable ties are the vital components to support the SFP+ DACs. Firstly, there is no doubt that the cable manager is designed for better cable management, as a very commonly used solution. And secondly, how about the strain relief bar? From its name, it is easy to learn that it is to support the cable by providing strain relief, which also facilitates the correct alignment of cable and connector into the port. Meanwhile, the strain relief bar also has the ability to keep the cables away from the spaces directly behind the server and switch equipment, reducing the thermal resistance through the equipment and promoting the effective cooling and airflow. Thirdly, cable ties should be used to hold the SFP+ DACs together and tie them to the strain relief bar and cable manager, although they looks so small and unimportant. What’s more, the cable tie installation should be done carefully to firmly place the cables, so that the cables will not move, and also not so tight as to deform or stress the cable jacket.

We all can’t deny that the SFP+ DAC provides an ideal low cost, low power and low latency solution for 10G short-distance connection deployment. In details, the cost of SFP+ DAC solution is up to three times less than that of fiber optical solution, the power it consumes is up to 50% less than that of current copper twisted-pair solution, and the latency is also lower than that of current copper twisted-pair solution. Furthermore, it features the smallest 10G form factor, as well as the overall cable diameter, designed for higher density and optimized rack space in 10G uplinks and 10G Fiber Channel SAN and NAS input/output connections. In short, the SFP+ DAC is an ideal solution to deploy 10G short-distance connection. If you are decide to deploy it, you are suggested to design and calculate the length of the SFP+ DACs your network needs and prepare the cable management tools to support the SFP+ DACs.

Breakout Panel Solutions for 10G to 40/100G Migrations

Although most data centers still deploy the 10 Gigabit Ethernet (GbE) networks, the 40/100 GbE networks have gradually become new and preferable options for them, which can be also reflected from the greatly increasing shipments of 40/100G optics. As the data of migration from 10G to 40/100G constantly grow, how to connect the 40/100G device with the existing 10G device in a fast and cost effective manner becomes a particularly vital concern of data center managers. To deal with this issue, experts come up with the MPO pre-terminated optical fiber cabling that is an ideal solution for smooth migration from 10G to 40/100G. In this paper, the breakout panel, a new kind of MPO pre-terminated product, will be studied that facilitates the 10G to 40/100G migration and enables simpler and more efficient network management.

The breakout panel used for 10G to 40G migration can be referred to as 40G breakout panel or 40G QSFP+ breakout panel, available in both single-mode and multimode versions with the color coded adapters. Just taking the 1RU 40G breakout panel as an example, there are 12 standard MTP connectors (8-fiber) elite to 48 duplex LC connectors, which can build up to 12-group breakout links for the 10G to 40G migration. What’s more, the 40G breakout panel can be designed with up to 96 ports for meeting the high density cabling demands, supporting 480G at most. In short, this kind of breakout panel is a good choice for making a high-performance and reliable straight connection from 10G to 40G.

We are used to choose the 24-fiber MTP to 10 duplex LC breakout cable to finish the 10G to 100G connection. When it is working, there are 20 fibers in the MTP side to transmit and receive 10G signals and 2 top and bottom fibers on the left and right unused, achieving the 10G to 100G connection. However, there is a serious problem caused if this kind of breakout cable is used for the application, which may increase cable congestion, clutter, tangling and confusion. In order to improve the efficiency and manage the cables better, the breakout panel used for 10G to 100G migration is published with more complicated design than 40G breakout panel. It is fitted with 8 24-MTP (20 fibers used) elite to 80 duplex LC in 1RU panel, which is able to deploy 8 groups of 10G to 100G connections in a simple, efficient and well maintained manner.

The breakout panel combines the advantages of MPO pre-terminated breakout cabling and compact patch panel that can not only solve the cable congestion issue but also save space and cost. Except that, it has various kinds of cabling standards that are available for the 10G to 40/100G migrations. In short, the breakout panel offers a perfect solution for the migration from 10G to 40/100G high density network. To better know the advantages of breakout panel, the following figure illustrates how does a 40G breakout panel work for the 10G to 40G application.

From the figure above, we can learn that the 40G breakout panel is very suitable for the 10G to 40G migration that features MTP interface to connect the 40G QSFP+ module and duplex LC interface to connect the 10G SFP+ module. With the use of 40G breakout panel, the 10G to 40G migration will be easily achieved, greatly meeting the requirements of high density and avoiding the cable congestion issue.

In order to gain higher network speed and larger bandwidth, the 40/100G network market is booming in recent years, which means the cabling network will be more and more complicated. In order to address the cable congestion issue and make the 10G to 40/100G migration in a smooth, efficient and well maintained manner, the 40G and 100 breakout panel are highly suggested. Besides, here offers an article that has more information about the breakout panel solutions.

Why Not Deploy 100G Ethernet Network?

Transceivers like Cisco SFP+, Juniper SFP+ are always used for deploying 10G Ethernet network, while transceivers like Cisco QSFP+, Juniper QSFP+ are chosen to deploy 40G Ethernet network if the network capacity and speed provided by the 10G Ethernet network are not able to meet our need. However, as our requirements for larger network capacity and higher network speed never stop, what should we do when the 40G Ethernet network can not satisfy our requirements any more? The answer is 100G Ethernet network, which is just a preferable solution to accelerate network speed for those bandwidth-hungry applications.

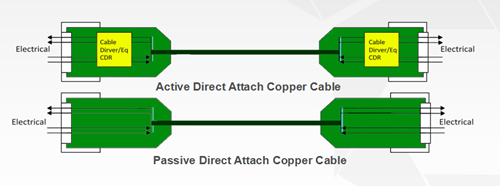

Since the 100G Ethernet network has been designed and put into use, the need for deploying 100G Ethernet network is always on the rise that can be learned from the following figure. What’s more, it is predicted that over half of the data center will migrate their systems to 100G Ethernet networks in near future. What makes the 100G Ethernet network so popular? What can we benefit from it? Let’s explore the advantages of deploying 100G Ethernet network.

In general, the advantages of 100G network can be concluded in four aspects. First and foremost, 100G network has the merits of expansion and scalability which is designed to support the reliability, manageability and flexibility of modern network while prepared for the bandwidth and speed requirements of future network. Due to allow for network changes in the future, 100G network can be still regarded as future-proofing network. Secondly, as a cost effective solution to greatly expand the network capacity, it features unsurpassed bandwidth and can be available at a compelling price. Thirdly, it is the first choice across long-haul networks for its large capacity and fast network speed that can be customized, optimized, and easily expanded to meet the future use. And finally, with the popularity of network transition from 10G/40G to 100G network, the 100G network technology is continuing to mature, which undoubtedly drives down the cost of 100G devices, such as QSFP28 transceiver modules and QSFP28 cables.

At present, there are several kinds of 100G transceivers, such as, QSFP28, CFP, CFP2 and CFP4, designed for different applications where the 40G transceivers can’t meet the requirements any longer. Among these 100G transceivers, the QSFP28 transceiver is the most widely used one which should be attached importance to for owning a fast, smooth and stable 100G network.

Similar to the QSFP+ transceiver that features four 10Gbps lanes to finish 40G transmission, the QSFP28 transceiver is also designed with four lanes, each of which transmits 25Gbps signal to achieve the whole 100G transmission and even supports the signal up to 28Gbps with an upgrade electrical interface. Meanwhile, the footprint and faceplate density of the QSFP28 transceiver are the same as those of the QSFP+ transceiver, but its advantages of higher density, lower power consumption and lower price per bit make itself superior to the QSFP+ transceiver.

When using QSFP28 to deploy 100G Ethernet network, you may be confused about some questions. For instance, why we should choose this kind of 100G transceiver? What is the difference between QSFP28 and QSFP+ transceiver? And how many QSFP28 transceiver modules can be fitted into one switch? The following will give you the answers for these problems, which may be useful for you to deploy a fast, smooth and stable 100G network.

Why we should choose QSFP28 transceiver to deploy 100G network? In contrast to other 100G transceivers like CFP family, QSFP28 has greatly increased the panel density and decreased power consumption which can save cost a lot. For example, the increase in density is even more dramatic when compared to other 100Gbps form factors, such as, 450% versus the CFP2. For this reason, it is highly recommended to use QSFP28 to deploy our 100G network.

What is the difference between QSFP28 and QSFP+ transceiver? These two transceiver modules have the same size form factor and the number of ports, while the lane speeds of QSFP28 transceiver are increased from 10 Gbps to 25 Gbps. Hence, the QSFP+ transceiver is always used for 40G transmission with the four 10 Gbps lanes, but QSFP28 transceiver features four 25 Gbps lanes to achieve 100G transmission.

How many QSFP28 transceiver modules can be fitted into one switch? Just taking the one rack-unit (RU) switch as an example, it generally accommodates up to 36 ports for QSFP28 transceiver modules. In addition, there are also many other kinds of transceivers and cables (DACs and AOCs) can be plugged into these ports.

100G Ethernet network is definitely a preferable solution to accelerate network speed and expand the network capacity, which is strongly suggested for those bandwidth-hungry applications. Meanwhile, QSFP28 transceiver module is the ideal choice to deploy the 100G network for large scale data centers, as well as future network expansions, which features higher port density, lower power consumption and lower cost. Since there have been several kinds of QSFP28 transceiver modules available on the market for different application, if you want to choose one proper QSFP28 transceiver for deploying your 100G network, you can visit this article that shows the basic knowledge of common QSFP28 transceiver modules.

Brief Introduction of Some Common Cable Lacing Bars

Various kinds of cable management tools like wire ties, J-Hooks, and cable lacing bars were designed and came into the market to meet the growing requirements of high density network, which enables better cable management. Among this tools, the cable lacing bar is one of the most common used cable management tool that can well manage the cables for rack or enclosure systems and keep the network in good performance and high effectiveness. In this paper, it will mainly introduce the knowledge of cable lacing bar and some common types of cable lacing bars, which is very useful for making the decision about which one should be chosen to manage cables.

Cable lacing bar is also referred to as lacer bar, generally made of metal material, which usually works with the wire ties or adjustable clips for providing support and management to the patch cables in rack or enclosure systems. As one of the most popular cable management tools, it only occupies 1/3 to 2/3 of a rack space and can secure and manage up to 24 cables in 1 RU that can greatly save space for installing other necessary devices. Meanwhile, the routing of cables will be also improved to a more neat one if the cable lacing bar is putting into use. Except that, it can stably control the bend radius of the patch cables so that these cables can not be damaged unexpectedly. As for its application, it can be mounted to the rear of a standard 19" rack or cabinet, or behind a patch panel, for better cable management.

Since there are basically six common cable lacing bar, round lacing bar, round lacing bar with offset, square lacing bar, L-shaped lacing bar, 90 degree bend lacing bar and horizontal lacing panel, available on the market and designed for specific cabling networks, the following will offer the information of these cable lacing bars for helping you choose the most suitable one to manage the patch cables in your network. Hope the information below would be useful for you.

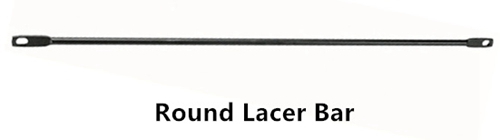

Round Lacing Bar

Round lacing bar features flattened ends, which diameter is 1/4 inch. If you want to know its appearance, you can learn it from the following figure. As for its application, if a small profile is required and small or individual horizontal cable runs in your network, you are highly recommended to use this kind of cable lacing bar for cable support and management.

Round Lacing Bar with Offset

Similar to the round lacing bar, the diameter of the round lacing bar with offset is also 1/4 inch, and its ends is flattened, too. As for its structure, it is shown in the following figure. Compared to the previous one, it can offer 1.5" offset or 4" offset for better cable management. In details, when lacing small bundles or individual cable off the rear of equipment, patch panels and other components, you can choose the round lacing bar with appropriate offset based on the distance from the rear of equipment to the rack rail and use it to relieve cable stress from the connections.

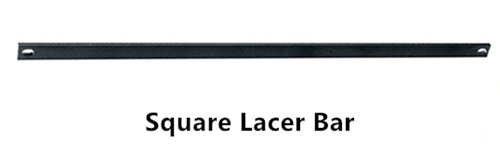

Square Lacing Bar

Square lacing bar still features 1/4" diameter rod and flattened ends, as shown in the figure below. It is a good choice for lacing cables vertically or horizontally, while also recommendable for cable routing at the rear of equipment.

L-shaped Lacing Bar

L-shaped lacing bar is much stronger than other kinds of lacing bars, which has fixed lacing points to support more patch cables. Unlike the round lacing bar with offset, this kind of lacing bar is available in 2", 4" and 6" offset to relieve cable stress. Its appearance is just like the letter L as its name implies, which can be also learned from the following figure.

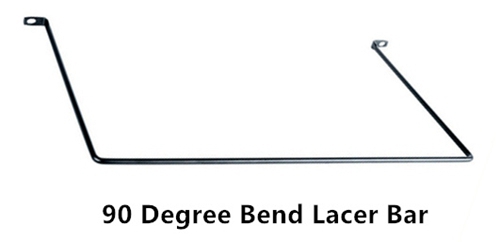

90 Degree Bend Lacing Bar

90 degree bend lacing bar, a special kind of lacing bar, which has some features in common with the offset round lacer bar, that provides full-width support to the cables and clearance around the components to extend past the rear rack rail (16-5/8" open width).

Horizontal Lacing Panel

Horizontal lacing panel is an ideal solution for the application where a lot of cables or mounting devices should be laced. In contrast to the previous cable lacing bars, it has the advantages of large flange, numerous cable tie points and more surface for mounting.

Cable lacing bar is a useful and cost effective cable management tool for rack or enclosure systems that are always works with the wire ties to support and manage the patch cables. It is able to avoid cable strain especially when trying to run cables from one side of the enclosure to the other, which also greatly saves space and highly improves the network to a more neat one. Any need for these kinds of cable lacing bars or wire ties can be satisfied at FS.COM who always offers the solutions for high density applications.

Wide-base J-Hook for Supporting Cat 5e Patch Cords

When holding and pulling the Cat 5e patch cords to deploy high density network, you should do some special handling for them, so that they can be more supported than the less-sensitive voice-grade cables used in traditional cable pulls. Why it is required? It’s because if you just use the narrow-base fasteners like cable ties and bridle rings to hang and support the cable bundles, the stress points will be created and the bend radius of Cat 5e patch cords will be exceeded. Under this condition, the Cat 5e patch cords are easy to be damaged by any overbending, twisting or stressing that may cause your network failure.

But how to make the Cat 5e cabling for ensuring the performance of the high density network? In fact, there are two solutions put forward to deal with the issue, the horizontal cabling tray and the J-Hook. Considering that the horizontal cabling tray solution is more expensive and time-consuming to install than the J-Hook one, so it is not recommendable at all. As for the J-Hook solution, it is much more practical, specially designed for high density network cabling. Let’s study the main features and advantages of the J-Hook solution and learn how to use the wide-base J-Hook for supporting the Cat 5e patch cords for better network cabling.

J-Hook is a special kind of fastener, usually made of galvanized steel but sometimes of plastic polymers, which can be installed in both indoor and outdoor high density application for supporting more than one Ethernet patch cable or cable bundle. It is easy to learn that its structure is like the letter “J” from its name, while from the following figure it is better to know its “J” structure that features a wide base with smooth and rounded corners and 90-degree angle bracket. This design is able to eliminate the potential for snags during installation, while preventing the development of stress points where the cable bundle is supported. As for its application, J-Hook can be easily and fast installed in various environments, such as beams, "C" or "Z" purlin, acoustical trees, drop wires, decks, and ceilings. In short, J-Hook offers an alternative solution to the cabling tray which is very cost effective to secure the cables like Cat 5e, Cat 6 and Cat 6a patch cords in the whole network.

As mentioned above, the wide-base J-Hook is specially designed to support the Ethernet patch cables. But how to use it to achieve the aim? Is it difficult to be installed? Let’s take the step by step procedures about using the wide-base J-Hook for supporting the Cat 5e patch cords in the following text as an example.

-

Firstly, attach the proper J-Hook--whether for wall, stud, beam, flange or drop-wire mounting--to the supporting structure. Space the J-Hooks to fall every 4 to 5 feet.

-

Secondly, put the Cat 5e patch cords in the J-Hooks. Ensure that the cable sag between the J-Hooks is less than 12 inches at midspan. If the sag is more than 12 inches, then you should add additional J-Hooks to support the cables. (Cable sag in actual application will rely on the number of cables in each bundle and the weight of the cables.)

-

Thirdly, if the J-Hook is able to work with the cable tie, you are suggest to use the prepunched holes in the J-Hook to install the tie. This prevents the Cat 5e patch cords from lifting. Be sure that the cable tie does not put pressure on the cables which may cause the geometry distortion of the cables.

-

Finally, check the whole installation and confirm there is no problem in the installation. Meanwhile, please ensure that the overall appearance of installed cable is neat.

Note: During the installation process, you should keep the cable-pulling tension constant and keep it below the EIA/TIA-568A specification for the Cat 5e patch cords.

J-Hook is a good solution to deploy and manage the Ethernet patch cables like Cat 5e patch cords in the high density network, which enables neat and high performance network, and money and time savings. In contrast with other cable management tools, it requires fewer materials and can be easier and faster to be installed. Hence, if choosing the J-Hook solution to manage the cables in high density environment, you can save a lot of time and money.